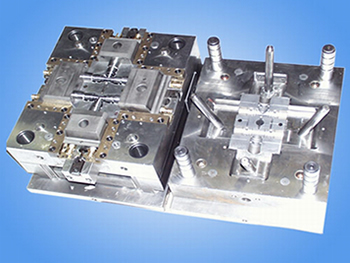

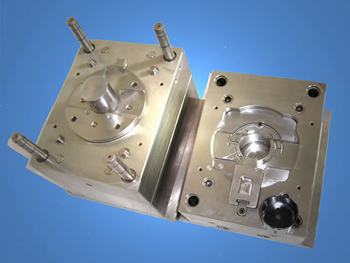

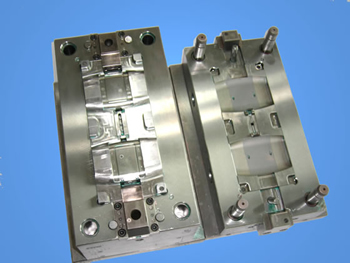

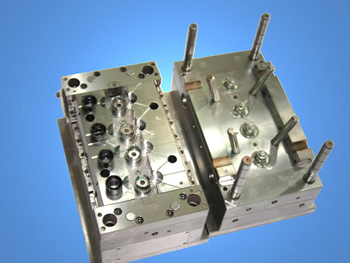

Our Mold making room is fully equipped to manufacture custom plastic molds and machined steel parts in-house, we are familiar with HASCO and DME standard after over 15 years’ focus on export market, Averagely we can supply 50 sets of mold per month, lead time is around 25~35days depends on the complexity of mold structure, mold bases supplies by LKM, mold steel and heat treatment with certificates apply to customer’s specification, maximum matching capacity 7.5ton minimum precision 0.005mm. Our Injection mold making capacities and experiences include: · Shuttle and Insert Molds · Expandable and Interchangeable molds · Multiple Slide Action Molds · Stripper and Floating Cavity Plate Molds · Hot Runner System · Unscrewing Molds · Double injection molds and two color injection molds Mold steel we frequently used: S136, S136H, NAK80, LKM2316, LKM738H, H13, etc. To lower down the cost and increase the efficiency for your companies, we pay special attention to injection mold making process control and manufacture correctness, as less as possible rework or mold trail out makes cost and lead-time as less as possible, we did it and are working on for better, in the past year, we had 97% positive feedback for the plastic injection molds we manufactured. |

||

|

|

|

|

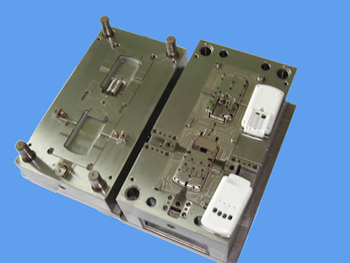

mould 01

|

mould 02

|

|

|

|

|

|

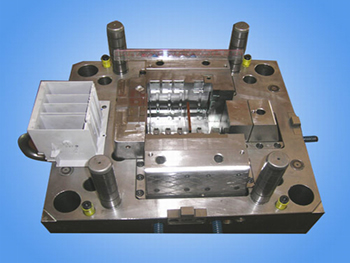

mould 03

|

mould 04

|

|

|

|

|

|

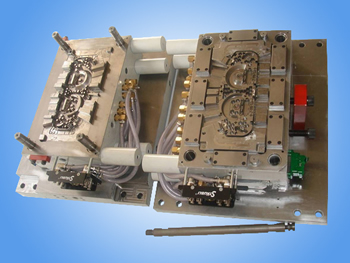

mould 05

|

mould 06

|

|

|

|

|

|

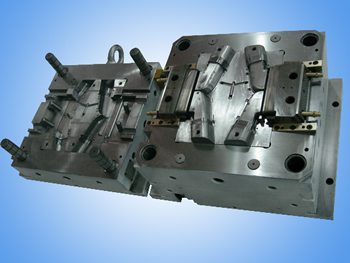

mould 07

|

mould 08

|

|

|

|

|

|

mould 09

|

mould 10

|

|

|

|

|||||

|

|

| Home | Factory | Manufacturing | Services | Quality | Products | Contact |

Copyright @2000 www.flextontec.com, All Rights Reserved. |